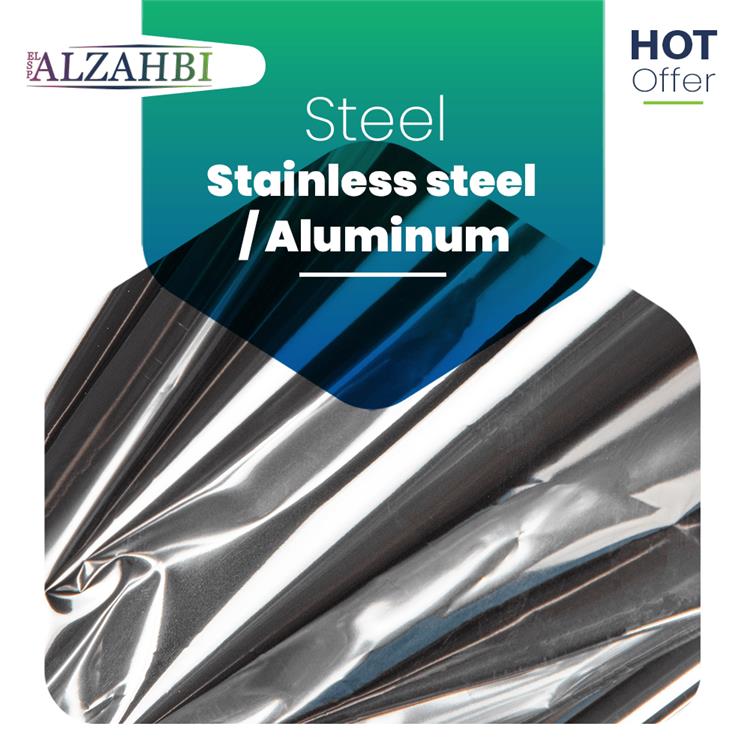

We offer a wide range of premium quality steel and aluminum tubes, ensuring superior performance, reliability, and consistency for your industrial needs in the UAE. Our tubes are manufactured to meet the highest standards, providing excellent strength, corrosion resistance, and durability for various applications.

Key Features and Benefits

- High Strength: Ensures excellent durability and performance in all applications.

- Versatility: Suitable for a wide range of industrial and commercial uses, including construction, manufacturing, and automotive.

- Consistent Quality: Provides reliable and consistent results across different applications.

- Corrosion Resistance: Available in various coatings to protect against corrosion.

- Customizable Specifications: Can be tailored to meet specific requirements, including dimensions, thickness, and length.

Applications of Steel and Aluminum Tubes

Construction

Steel and aluminum tubes are widely used in the construction industry for structural components, scaffolding, and framework. Their high strength and durability ensure the stability and safety of buildings and infrastructure projects.

Manufacturing

In the manufacturing industry, steel and aluminum tubes are used to produce machinery, equipment, and industrial components. Their versatility and reliability make them suitable for a broad range of manufacturing applications.

Automotive

Steel and aluminum tubes are essential in the automotive industry for making exhaust systems, roll cages, chassis, and other components. Aluminum's excellent strength-to-weight ratio makes it ideal for producing high-performance, fuel-efficient vehicles.

Furniture

Steel and aluminum tubes are used in the production of furniture, including tables, chairs, and storage systems. Their durability and aesthetic appeal make them ideal for both residential and commercial furniture applications.

HVAC

Tubes are used in heating, ventilation, and air conditioning (HVAC) systems for ductwork, heat exchangers, and condensers. Their thermal conductivity and corrosion resistance ensure efficient and long-lasting performance.

Marine

In the marine industry, steel and aluminum tubes are used for constructing boats, ships, and offshore structures. Their corrosion resistance ensures durability and reliability in harsh marine environments.

Why Choose Our Steel and Aluminum Tubes?

- Trusted Quality: Our tubes are produced under strict quality control to ensure high strength and consistent performance.

- Versatility: Suitable for a wide range of applications, providing reliable solutions for various industrial needs.

- Local Expertise: Tailored solutions for the UAE market, supported by local technical expertise and customer service.

- Environmental Compliance: Meets and exceeds environmental standards, promoting sustainable and eco-friendly industrial practices.

Learn More About Steel and Aluminum Tubes

For a comprehensive understanding of steel and aluminum tubes, including their detailed properties, benefits, and various applications, we invite you to read our Aluminum Tubes article. This article provides valuable insights into how our tubes can meet your specific industrial needs, from construction to automotive manufacturing.

Frequently Asked Questions

What are steel and aluminum tubes used for?

Steel and aluminum tubes are used in various applications, including construction, manufacturing, automotive, furniture, HVAC systems, and marine. Their high strength, versatility, and corrosion resistance make them invaluable in these industries.

How do steel and aluminum tubes benefit the construction industry?

Steel and aluminum tubes provide high strength and durability, making them ideal for structural components, scaffolding, and framework. They ensure the stability and safety of buildings and infrastructure projects.

Are your steel and aluminum tubes suitable for automotive manufacturing?

Yes, our high-quality steel and aluminum tubes are suitable for automotive manufacturing, providing the necessary strength and formability for making exhaust systems, roll cages, chassis, and other components.

Contact Us

For more information about our steel and aluminum tube products and to place an order, contact us today. Our team is ready to assist you with tailored solutions to meet your specific needs.

Call Us at:

+971 55 306 4383